Phone:

(86) 18875820576

Physical address:

No.24 Building, Nansheng Industrial Area, Daikou, Pingyang, Wenzhou, China 325402

Pp woven bag is the most popular packaging bag for both agricultural and industrial products.

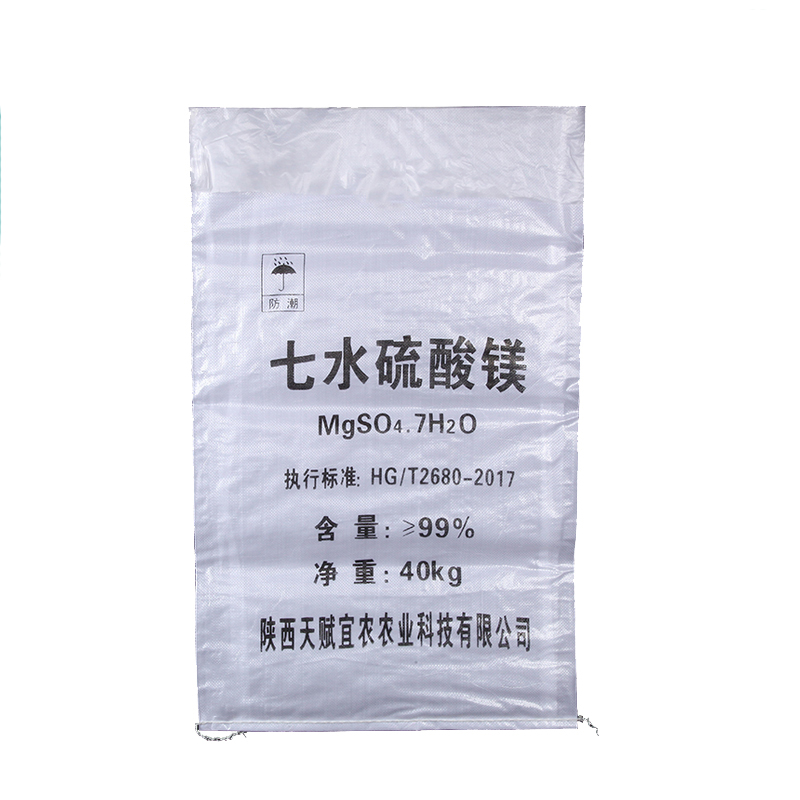

The advantage of pp woven is cost-effective, light weight compared with traditional packaging. Color of pp woven bag can be transparent, white and other customized colors.

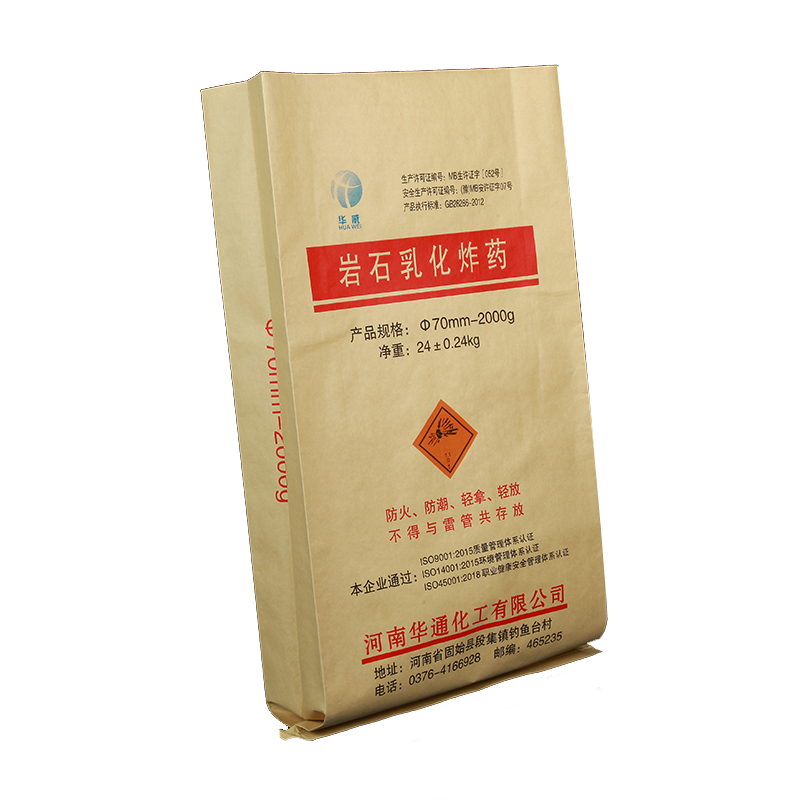

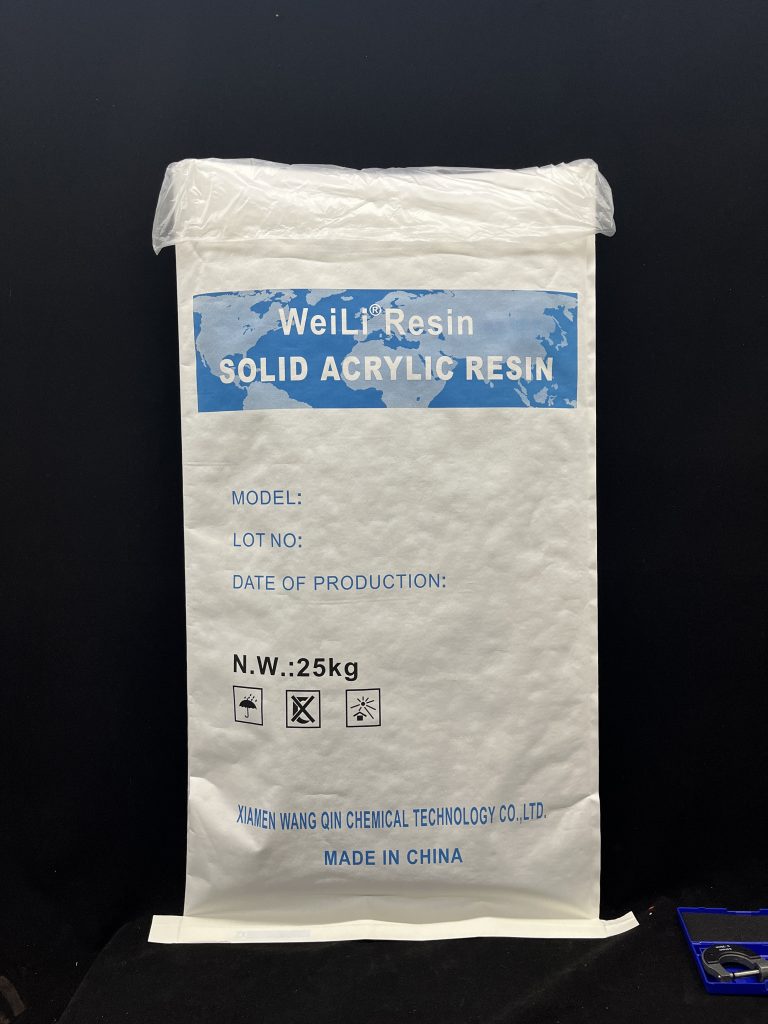

Kraft paper-pp woven bag is another packaging bag widely used for industrial products, for plastic granules, chemical products, the bag is thicker, firm and durable use.

PP woven bag with liner is frequently used for powder, granules products. For agricultural products, especially for fertilizer packing, the liner can be separated with outer bags or sewn together with outer bags depends on customer’s demand.

The bottom of pp woven bags can be thread stitched or made square bottom. Square bottom makes the bag more solid after filled with products, and stack more neatly. This is usually used for high-cost products.

Flexible packaging bags bags usually used for food packaging, also for other products. The flexible packaging is made of many kinds of materials: paper, aluminum, pet, pe, nylon etc…According to the usage of bags, the material, shape of bags can be different.

FFS bags usually use multi-layer composite film materials. Common materials include polyethylene (PE), polypropylene (PP), aluminum foil, etc. The choice of specific materials depends on the preservation needs of the product, such as moisture-proof, oxidation-proof, etc.

Who We Are

Zhejiang Kondin Plastic Co.,Ltd is a leading packaging supplier established in Year 2024, and Kondin is headquartered in Xiaojiang, Wenzhou, China, which is a famous packaging industrial town. Kondin is a modern enterprise specializing in packaging design, production and sales. The company is committed to providing customers with a full range of packaging solutions and helping customers enhance their brand value and market competitiveness with high-quality products, innovative designs and excellent services.

Our product lines cover a wide range of products, including paper packaging, plastic packaging, environmentally friendly packaging materials and customized packaging solutions. Whether it is packaging needs for agricultural, industrial products or other industries, we can provide personalized and innovative designs based on customers’ specific requirements.

Over the years, Kondin has won the trust and cooperation of many well-known brands at home with its high-quality products and services, and we are willing to enlarge our sales to abroad to more customers. We adhere to the concept of “customer first” and are guided by customer needs. We are committed to establishing long-term and stable cooperative relationships with customers and jointly promote the development and growth of our business.

Serving All Markets

Feed packaging bags play an important role in agriculture and animal husbandry. They can not only effectively protect the quality of feed, but also facilitate storage and transportation.

Fertilizer packaging bags are crucial in agriculture, serving to protect the quality of fertilizers, facilitate transportation and storage, and provide necessary information to users.

Plastic food packaging occupies an important position in the modern food industry. Because of its lightness, durability and versatility, it is widely used in the packaging of various foods, for example: rice, maize, flour, noodles etc.

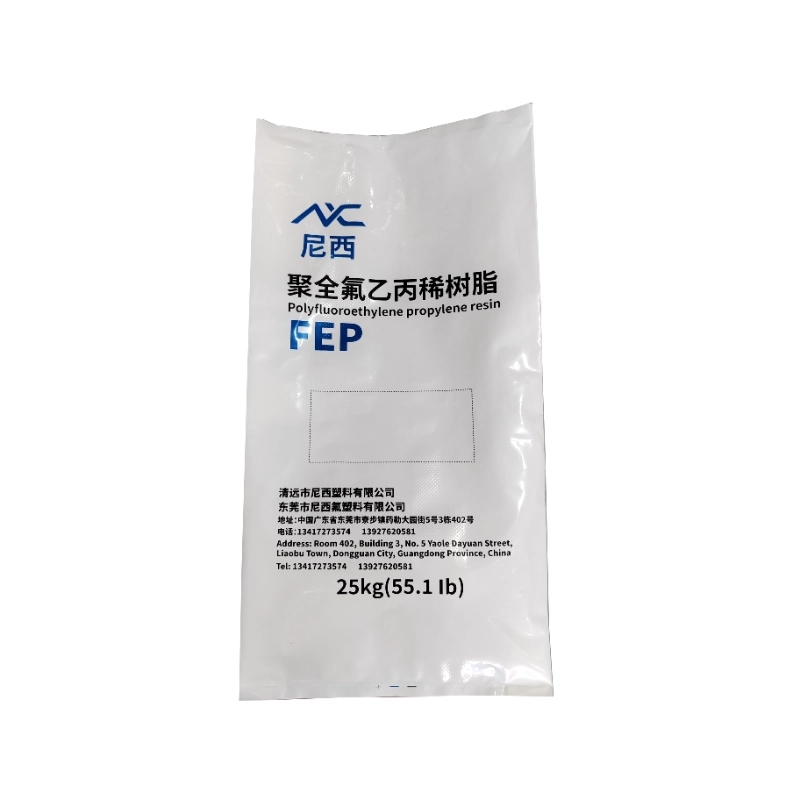

PP woven bags and PE heavy bags are two main packaging bag for plastic or chemical materials.

Due to its light weight and firm features, these two packaging bag are no doubt the first choice.

Seed packaging bags are essential for preserving the quality, viability, and longevity of seeds until they reach the end user, whether a farmer, gardener, or consumer. These bags must protect seeds from moisture, light, pests, and physical damage while also providing important information about the seed variety, planting instructions, and regulatory compliance.

Pls provide us the detailed information for products, for example:

Cylinder cost or plate cost is necessary for bags with printing. Customers’ printing logo is manufactured on cylinder or plate so that we can make printing. Usually it is paid for first time. And we have policy if the quantity reach certain number, plate cost will be refund.

Yes, we can send suggestion to you according to the usage and capacity of bags, and we free sample can be sent for you to make test.

Yes, sure we can send free samples.

The delivery time depends on quantity you need. For minimum order quantity 10000pcs, usually it takes 7-10days.

The paper packaging bag with folding handle is a newly designed packaging. Overall body of the bag is made of papers: three layer of papers. And there is a paper string pasted on the backside of the bag. When packaging is done and gas exhausted, the paper bag can be folded and tie the string, which will naturally formed a handle. This paper packaging bag with folding handle is popular in Japan market. Due to the environmental awareness and limit usage of plastic, paper material is welcomed in Japan.

PP woven bags are widely used for many fields, including for bulk flour packing. First, polypropylene(PP) is a good material which has advantage of strength, so it is a very good choice for packing flours like 25kg, 50kg. Second, PP woven bag is a material with low cost compared with other materials, so it is welcomed among customers. There are many kinds of PP woven bags with different material grades, the first choice is virgin PP material, the bag is bright white and good quality. And pattern of the pp woven flour bag can be overlapped, which means adding the…

Paper-plastic bags are a form of packaging that combines the advantages of paper and plastic materials. Its structure is usually composed of an outer layer of kraft paper and an inner layer of plastic film. It has high strength, moisture resistance and environmental protection. It has a wide range of applications in the industrial field. application: Chemical industry: Paper-plastic bags are often used to package chemical products such as fertilizers, resins, and pigments. These products are often corrosive to a certain extent, and the plastic film on the inner layer of the paper-plastic bag can provide good anti-corrosion protection. Building…